3D CONCRETE PRINTING: A STEP TOWARDS DEVELOPMENT IN INDIA

Written by: Monomita Chakraborty

Publish Date: December 31, 2020

Developing nations such as India have long struggled with urban cities’ slumification, pollution, and population growth. On the other hand, in terms of technology and the materials used, concrete 3d-printing has achieved a certain sophistication in other countries.

Significant policy reforms in Indian metropolitan cities such as Mumbai and Delhi are also needed to mitigate the urban housing crisis. These reforms will speed up building times but create environmental concerns because bricks and cement constitute the principal source of building materials. The environmental burden of this policy-driven construction push may be minimized by a significant technological change in materiality. For the adoption of these sustainable products, which may be difficult to introduce in a competitive market, a push is required.

According to India CSR Network, “With India’s aggressively pursuing the objective of creating 60 million houses under the Housing for All by 2022 programme, this achievement will certainly give a huge boost for the mass housing segment.”

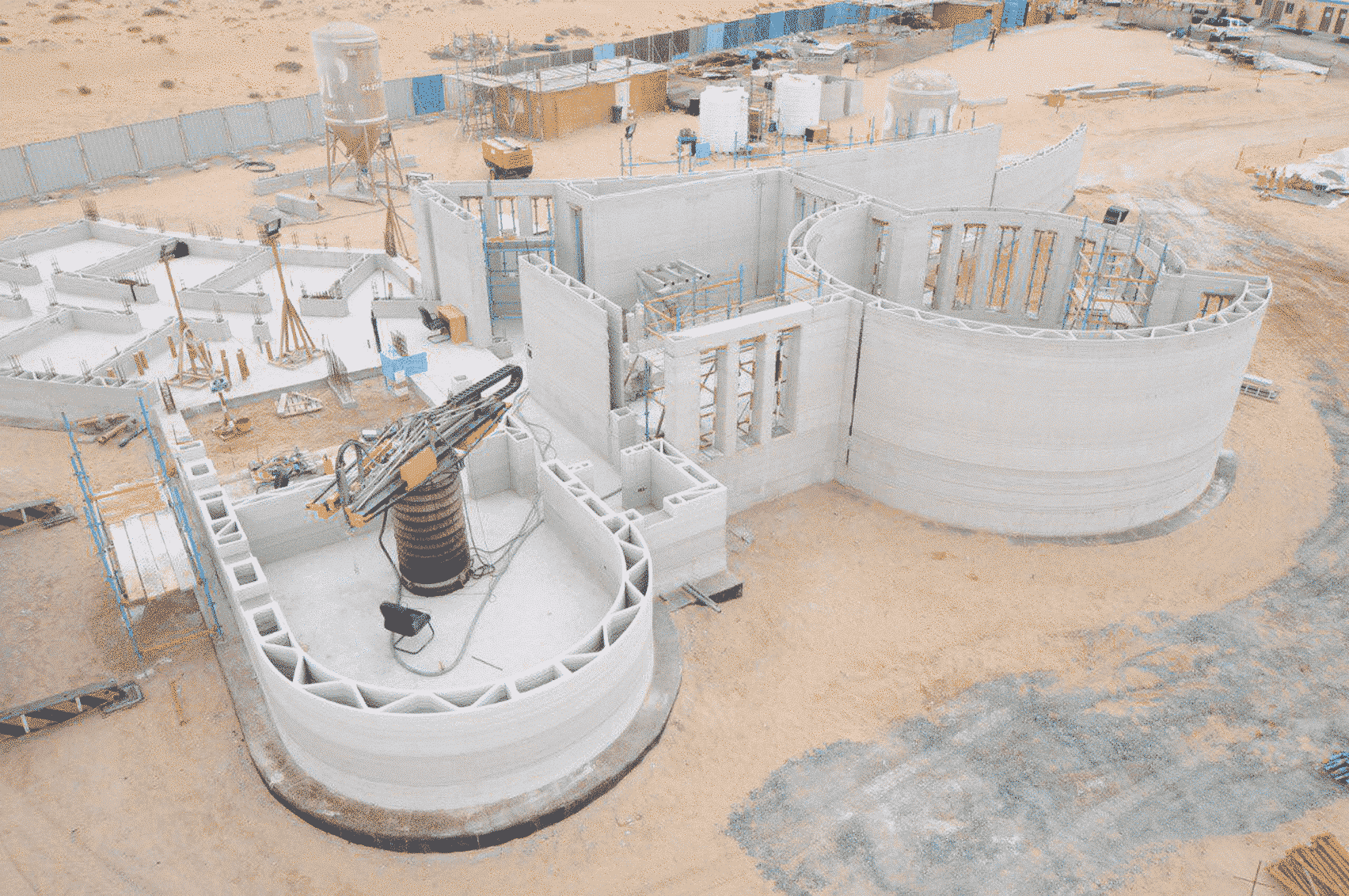

3D concrete printing is a type of additive manufacturing used to produce entirely new shapes of buildings or construction components that were previously not possible with conventional concrete shapes.

Much as 3D printing and additive manufacturing are used by manufacturing to build jigs, machines, and other fixtures used in the manufacturing process, 3D printing can be used by the robotics industry as part of their engineering design process and to construct and produce their designs.

In the construction industry, the big benefit of using 3D printing is to save a lot from material waste production costs. That’s because a 3D printer uses exactly the amount of material they need, including robotic weapons. Also, it can save a lot of time.

The robotic arm extruder is a perfect example of how to use 3D printing in the construction industry. The way FDM desktop 3D printers work is fairly close. In order to make the robotic arm move, the rails are arranged; and within the limits of the rails, by extruding concrete material from the nozzle, the arm will create the house layer by layer. This is the most common technology used to create XL structures for 3D printing.

What is 3D Printing?

In order to create a 3-dimensional object, usually layer by layer, 3D printing is a process in which the material is printed under computer control. Printing quick prototypes, complex shapes, and small-batch processing using special polymers, metal alloys, etc. is primarily used in manufacturing industries. 3D concrete printing is still mostly in development across the globe.

By 2024, the sector is expected to grow to $35.6 billion. Most of the growth in the 3D printing industry is under development. Although the sector is increasing, initiating large-scale construction is a slow process. Although 3D printing is not used in bridge-building every day, it has great possibilities.

According to YourStory, “Recently, faculty and alumni of the Indian Institute of Technology, Madras (IIT-M) developed what is touted as India’s first 3D printing technology. To prove the technology’s efficiency, the team built its first successful 3D structure. It claimed that with this indigenous technology, a 350 sq ft house can be built within a week’s time at a cost lesser than what a conventional house would take to build.”

Larsen & Toubro is a multinational Indian corporation that invests over USD 21 billion in sales, engineering, procurement, construction, development, defense, and services projects. It operates in more than thirty countries.

L&T had 3D printed 240 square feet 1 BHK earlier in November 2019, in line with the traditional EWS (Economically Weaker Sections) construction layout to explore the feasibility of this revolutionary technology.

Like a 3D printer, it is both sustainable and time-efficient to print homes because it can be configured to reduce waste, operate on limited power, and work round the clock. The time efficiency makes it possible to complete the building in a short period of time, thereby enabling developers to create more houses.

The future of 3D printing is vibrant and a significant cornerstone in the revival of manufacturing. There are now a number of use cases and quantifiable market advantages showing that additives can be used as a mainstream production technology.

About the Author

This article is written by Monomita Chakraborty

Read the original post here.